Process of Arita Ware Production

The primary raw material for Arita ware is fine porcelain claystone, which was discovered at Mount Arita-Izumi in what is now Arita town in 1616, when it then started to be quarried. Nowadays, the porcelain claystone of the Amakusa region is used instead.

The primary raw material for Arita ware is fine porcelain claystone, which was discovered at Mount Arita-Izumi in what is now Arita town in 1616, when it then started to be quarried. Nowadays, the porcelain claystone of the Amakusa region is used instead.

![]()

Quarried claystone is crushed and reduced to powder. This process needs to be done slowly. If the claystone is crushed too quickly, it can cause the claystone to heat up and lose its viscous properties, which are necessary for the claystone to be formed later.

Quarried claystone is crushed and reduced to powder. This process needs to be done slowly. If the claystone is crushed too quickly, it can cause the claystone to heat up and lose its viscous properties, which are necessary for the claystone to be formed later.

![]()

Powdered claystone is added to water and stirred well, then left to settle for a while, allowing some heavy impurities and gravel to sink.The water, containing fine claystone particles, is filtered to make fine clay.This process is repeated several times in order to get good quality clay.

Powdered claystone is added to water and stirred well, then left to settle for a while, allowing some heavy impurities and gravel to sink.The water, containing fine claystone particles, is filtered to make fine clay.This process is repeated several times in order to get good quality clay.

![]()

The semi-liquid claystone mixture is compressed, which removes excess fluid.

The semi-liquid claystone mixture is compressed, which removes excess fluid.

![]()

Various materials are added to the claystone mixture, in order to, amongst other things, improve its strength and make the finished product glaze smoothly. The mixture is then well ‘pugged’ - a process which involves working the material into a soft clay and removing air pockets. Good pugging is essential because poorly mixed clay or any air trapped in the clay can cause products to develop an uneven shape or even break during firing.

Various materials are added to the claystone mixture, in order to, amongst other things, improve its strength and make the finished product glaze smoothly. The mixture is then well ‘pugged’ - a process which involves working the material into a soft clay and removing air pockets. Good pugging is essential because poorly mixed clay or any air trapped in the clay can cause products to develop an uneven shape or even break during firing.

![]()

Forming is performed by various techniques: potter’s wheel, hand, molding and casting for example. The clay is semi-dried during the forming process, and is known as greenware, or namakiji in Japanese. Namakiji can crack and break easily, so it should be handled with care.

Forming is performed by various techniques: potter’s wheel, hand, molding and casting for example. The clay is semi-dried during the forming process, and is known as greenware, or namakiji in Japanese. Namakiji can crack and break easily, so it should be handled with care.

![]()

The greenware is low-fired at 900 degrees so as to make it dry and firm.

The greenware is low-fired at 900 degrees so as to make it dry and firm.

![]()

Designs are painted onto the surface of a low-fired body. Sometsuke (blue and white painting) is done at this point of the process.

Designs are painted onto the surface of a low-fired body. Sometsuke (blue and white painting) is done at this point of the process.

![]()

The glaze is poured evenly over the greenware, which is then put on a board. The glaze is removed from the underneath of the product to avoid it sticking to the board.Glazing makes products smooth like glass, non-porous and stain-resistant. The pieces are left to dry well after glazing.

The glaze is poured evenly over the greenware, which is then put on a board. The glaze is removed from the underneath of the product to avoid it sticking to the board.Glazing makes products smooth like glass, non-porous and stain-resistant. The pieces are left to dry well after glazing.

![]()

The pieces are fired in a gas kiln at 1,300 degrees for about 16 hours.The characteristics of porcelain, such as its translucent color and its coolness of touch, become apparent at this stage of the process.

The pieces are fired in a gas kiln at 1,300 degrees for about 16 hours.The characteristics of porcelain, such as its translucent color and its coolness of touch, become apparent at this stage of the process.

![]()

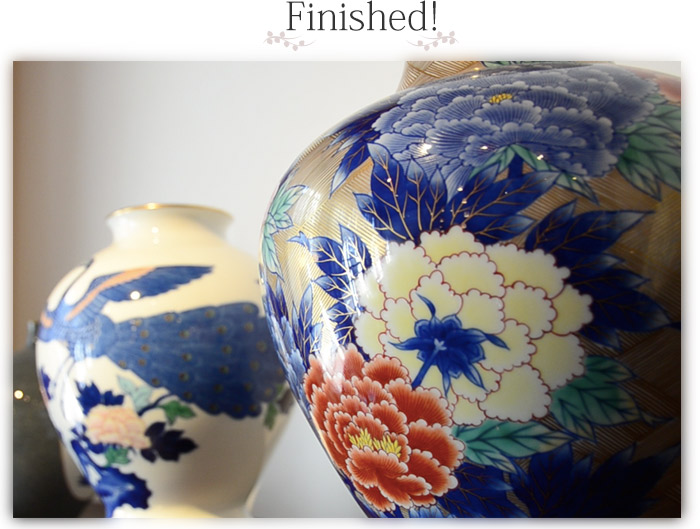

Painting on the high-fired glazed pieces with colors other than cobalt blue now takes place. Common colors for Arita ware are red, green, yellow and gold. Akae: overglazed color painting on white porcelain. Somenishiki: Overglazed colored painting on a Sometsuke (blue and white painting) background.

Painting on the high-fired glazed pieces with colors other than cobalt blue now takes place. Common colors for Arita ware are red, green, yellow and gold. Akae: overglazed color painting on white porcelain. Somenishiki: Overglazed colored painting on a Sometsuke (blue and white painting) background.

![]()

The overglazed painted pieces are fired at 700-800 degrees.

The overglazed painted pieces are fired at 700-800 degrees.